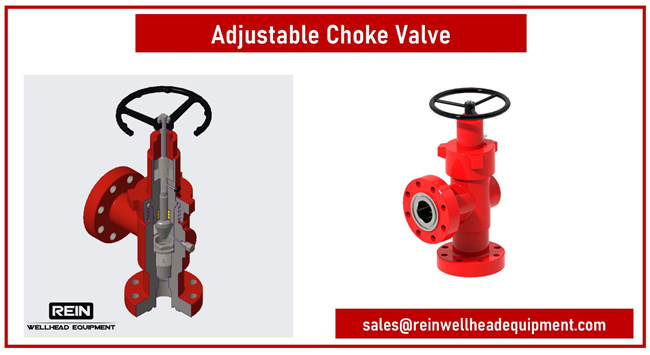

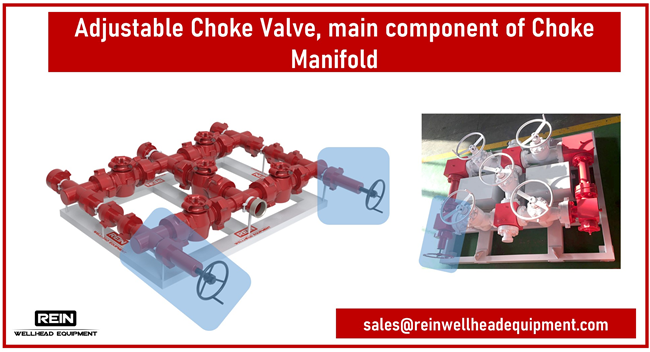

Adjustable Choke Valve is a special angle valve designed to reduce pressure of well stream to the required level, so upstream equipment may handle fluids and gases more safely and effectively. Adjustable Choke Valve is often used as a component of wellhead and Christmas tree assemblies, choke manifolds, in-line heaters, desanders and other oilfield equipment. There are two types of commonly used choke valves, adjustable choke valve and positive (bean) choke valves.

Blow is an additional description of adjustable choke valves

The choke is used to control the production, perhaps to prevent sand production or to maintain the most efficient rate for the well. The choke restricts the area available for flow through a beam or orifice of a specified diameter that must be inserted into the choke body. The smaller the diameter of the beam the lower the production rate. There are two different kinds of chokes, the positive chokes with interchangeable beans, and adjustable chokes, which allow the choke size to varied more easily.

Rein Wellhead Equipment designs, fabricates and supplies adjustable choke valve as a separate item or as part of valve assembly, such as Oil & Gas Christmas tree, Choke Manifold, Water Bath Heaters, etc. Rein is a qualified and certified supplier and manufacturer of choke valves, as well as other products as per API 6A and API 16. Feel free to contact Rein for more information and price.

Code & Standards

API 6A |

NACE MR-0175 |

ISO 15156-1, -2 |

ASME B31.3 |

PED 97/23/EC |

Standards | API 6A |

Environment temperature | from -60°С to +40°С |

Working temperature | LU (51℉/-46℃ ~ 250℉/121℃) |

Material Grades | AA, BB, CC, DD, EE, FF, HH, FF |

Specification level | PSL1 - PSL4 |

Performance level | PR1, PR2 |

Material Class | Min. Material Requirements | |

Outer parts | Internals | |

AA | Carbon or Low Alloy Steel | Carbon or Low Alloy Steel |

BB | Carbon or Low Alloy Steel | Stainless Steel |

CC | Stainless Steel | Stainless Steel |

DD | Carbon or Low Alloy Steel | Carbon or Low Alloy Steel |

EE | Carbon or Low Alloy Steel | Stainless Steel |

FF | Stainless Steel | Stainless Steel |

HH | Corrosion Resistant Alloy | Corrosion Resistant Alloy |

ZZ | Determined by User | Determined by User |

Note: Classes from DD shall be NACE MR0175/ISO 15156 compliant

API Classification | Operating Temperature | |||

Min (°C) | Max (°C) | Min (°C) | Max (°C) | |

K | -60 | 82 | -75 | 180 |

L | -46 | 82 | -50 | 180 |

N | -46 | 60 | -50 | 140 |

P | -29 | 82 | -20 | 180 |

S | -18 | 60 | 0 | 140 |

T | -18 | 82 | 0 | 180 |

U | -18 | 121 | 0 | 250 |

V | 2 | 121 | 35 | 250 |

X | -18 | 180 | 0 | 350 |

Y | -18 | 345 | 0 | 650 |