CONTACT US

-

Mob:

+86 135 2595 3919 -

Tel:

+86 135 2595 3919 -

Email:

sales@rein-pe.com -

Add

402, B40, TusCity, Suzhou Industrial Park, Suzhou, 215122, Jiangsu, China

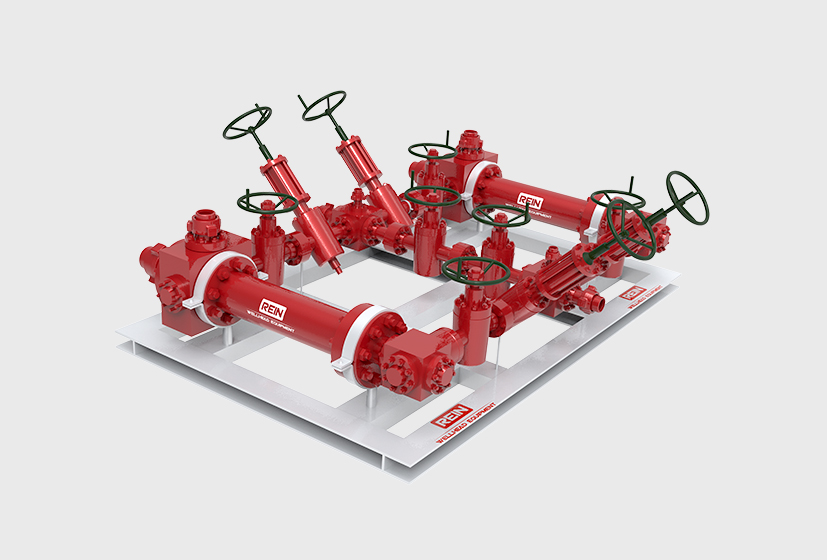

Double Barrel Debris Catcher with Hydraulic Valves

Double Barrel Debris Catcher with Hydraulic Valves

Double Barrel Debris Catcher with hydraulic and manual gate valves allow the oilfield service to conduct flowback and well clean-up works continuous without work interruption due to the maintenance of debris catcher. Barrels of debris catcher ensures separation of trash coming from formation after the hydraulic fracturing, hydraulic slab gate valves ensure remote flow control, while manual gate valves provide additional means of flow control in case of unavailability of hydraulic power.

Rein supplies single- and double-barrel reliable debris catcher manifolds with hydraulic and/or manual slab gate valves. Manifold is designed with deep consideration to ease transportation and operation of manifolds. Rein also supplies control panels to control and monitor hydraulic slab gate valves.

.png)

Pressure rating of Single Barrel Debris Catcher

MPa | 35 | 70 | 105 |

psi | 5000 | 10000 | 15000 |

Sizing of Single Barrel Debris Catcher

Inlet Connection | 2” Fig.1502, 3” Fig.1502, API Flange 3.1/16”-10K/15K, API Flange 4.1/16”-10K/15K, API Flange 5.1/8”-5K, |

Outlet Connection | 2” Fig.1502, 3” Fig.1502, API Flange 3.1/16”-10K/15K, API Flange 4.1/16”-10K/15K, API Flange 5.1/8”-5K, |

Catcher Barrel Sizing

In. | 3 | 4 | 5 | 6 | 7 |

Code & Standards

API 6A |

NACE MR-0175 |

ISO 15156-1, -2 |

ASME B31.3 |

PED 97/23/EC |

Standards | API 6A |

Environment temperature | from -60°С to +40°С |

Working temperature | LU (51℉/-46℃ ~ 250℉/121℃) |

Material Grades | AA, BB, CC, DD, EE, FF, HH, FF |

Specification level | PSL1 - PSL4 |

Performance level | PR1, PR2 |

Material Class | Min. Material Requirements | |

Outer parts | Internals | |

AA | Carbon or Low Alloy Steel | Carbon or Low Alloy Steel |

BB | Carbon or Low Alloy Steel | Stainless Steel |

CC | Stainless Steel | Stainless Steel |

DD | Carbon or Low Alloy Steel | Carbon or Low Alloy Steel |

EE | Carbon or Low Alloy Steel | Stainless Steel |

FF | Stainless Steel | Stainless Steel |

HH | Corrosion Resistant Alloy | Corrosion Resistant Alloy |

ZZ | Determined by User | Determined by User |

Note: Classes from DD shall be NACE MR0175/ISO 15156 compliant

API Classification | Operating Temperature | |||

Min (°C) | Max (°C) | Min (°C) | Max (°C) | |

K | -60 | 82 | -75 | 180 |

L | -46 | 82 | -50 | 180 |

N | -46 | 60 | -50 | 140 |

P | -29 | 82 | -20 | 180 |

S | -18 | 60 | 0 | 140 |

T | -18 | 82 | 0 | 180 |

U | -18 | 121 | 0 | 250 |

V | 2 | 121 | 35 | 250 |

X | -18 | 180 | 0 | 350 |

Y | -18 | 345 | 0 | 650 |

If you require any further information,feel free to contact us

We would be glad to provide you immediate technical assistance and cost-effective proposal!

CONTACT BY PHONE CONTACT BY EMAIL