CONTACT US

-

Mob:

+86 135 2595 3919 -

Tel:

+86 135 2595 3919 -

Email:

sales@rein-pe.com -

Add

402, B40, TusCity, Suzhou Industrial Park, Suzhou, 215122, Jiangsu, China

Tubing Hangers

Tubing Hangers

A tubing hanger typically is threaded onto the top of a tubing string and is designed to sit and seal in the tubing head. Usually the tubing hanger is run through the BOP and landed in the top bowl of the tubing head. The top of the tubing hanger provides a profile necessary for the lock screws that will secure the hanger in the tubing head.

Tubing Hangers are manufactured in a wider variety of types and sizes than any other single component in the wellhead system. They must be configured to meet the needs of a basic completion or the increasingly complex well completion requirements of 21st Century oil and gas wells.

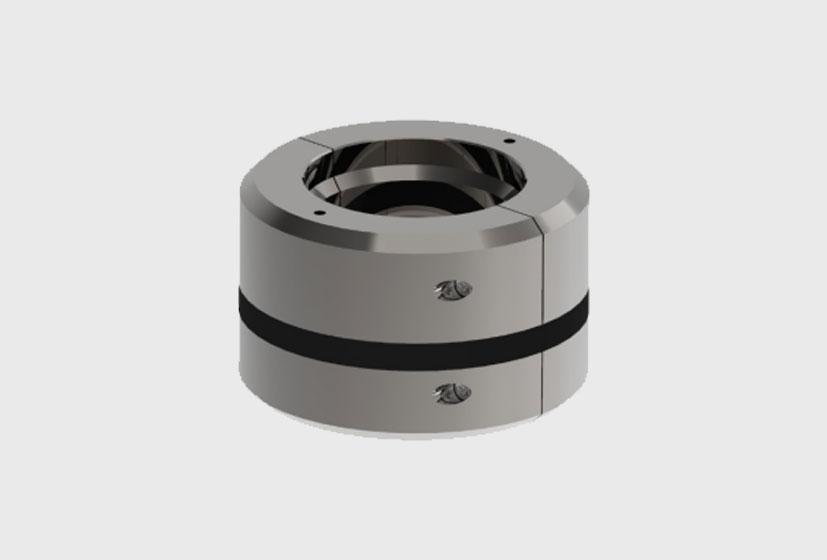

TC-1W Wrap-Around Tubing Hanger

Reliable compression seal controls annulus pressure during Christmas Tree installation.

Available in standard API tubing sizes.

Technology parameters

Bowl Size | Tubing Size | Working Press. | Product Specification Level | Material Class |

7” | 2.3/8” ~ 4.1/2” | 3K ~15K | PSL 1 ~ PSL 3 | AA, DD, EE, FF |

11” | 3.1/2” ~ 7” | 3K ~15K | PSL 1 ~ PSL 3 | AA, DD, EE, FF |

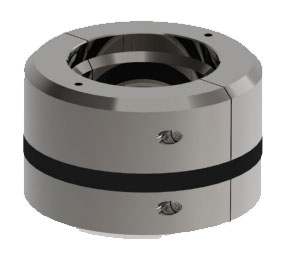

TC-1A Mandrel Tubing Hangers

Reliable compression seal controls annulus pressure during Christmas Tree installation. Lift and suspension threads are available in standard tubing sizes and threads; BPV prep not available on this type tubing hanger.

Available in standard API tubing sizes.

Technology parameters

Bowl Size | Tubing Size | Working Press. | Product Specification Level | Material Class |

7” | 2.3/8” ~ 4.1/2” | 3K ~15K | PSL 1 ~ PSL 3 | AA, DD, EE, FF |

11” | 3.1/2” ~ 7” | 3K ~15K | PSL 1 ~ PSL 3 | AA, DD, EE, FF |

TC-1A-EN Extended Neck Tubing Hanger

This tubing hanger is a threaded mandrel type tubing hanger with an extended neck. This hanger utilizes "S" type seals on its neck that are used to seal in the tubing head adapter. This hanger can be configured with interference type “S” seal or compression packing on the body to affect an annular seal. Lock down screws are used to both energize this packing as well as lock the hanger into the tubing head bowl.

Available in standard API tubing sizes.

Technology parameters

Bowl Size | Tubing Size | Working Press. | Product Specification Level | Material Class |

7” | 2.3/8” ~ 3.1/2” | 3K ~15K | PSL 1 ~ PSL 3 | AA, DD, EE, FF |

11” | 3.1/2” ~ 7” | 3K ~15K | PSL 1 ~ PSL 3 | AA, DD, EE, FF |

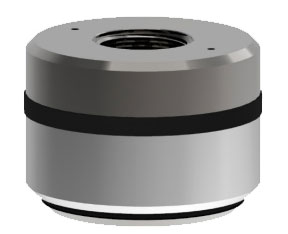

BO-2 Coupling

This coupling type tubing hanger uses a one piece coupling that is externally threaded with a ACME thread. The internal landing and suspension threads match the customer tubing specifications. Additionally, the BO-2 coupling incorporates a back pressure valve, (BPV) profile in the I.D. The BO-2 coupling is used with the TC-1W pack-off and is system of choice whenever the tubing string needs to be manipulated to set run in conjunction with a TC-1W wrap around type pack-off.

Available in standard API tubing sizes.

Technology parameters

Flange Size | Tubing Size | Working Press. | Product Specification Level | Material Class |

7.1/16” | 2.3/8” ~ 3.1/2” | 3K ~10K | PSL 1 ~ PSL 3 | AA, DD, EE, FF |

If you require any further information,feel free to contact us

We would be glad to provide you immediate technical assistance and cost-effective proposal!

CONTACT BY PHONE CONTACT BY EMAIL