CONTACT US

-

Mob:

+86 135 2595 3919 -

Tel:

+86 135 2595 3919 -

Email:

sales@rein-pe.com -

Add

402, B40, TusCity, Suzhou Industrial Park, Suzhou, 215122, Jiangsu, China

H2S Removal Equipment

H2S Removal Equipment

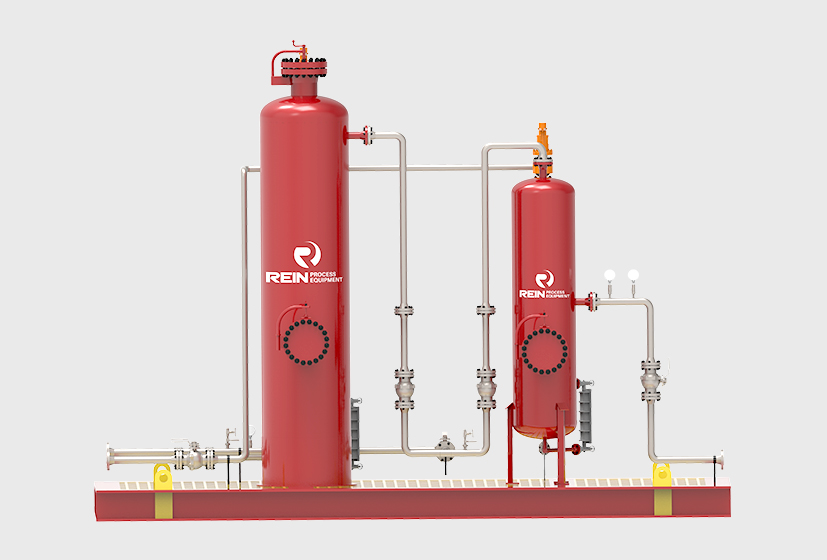

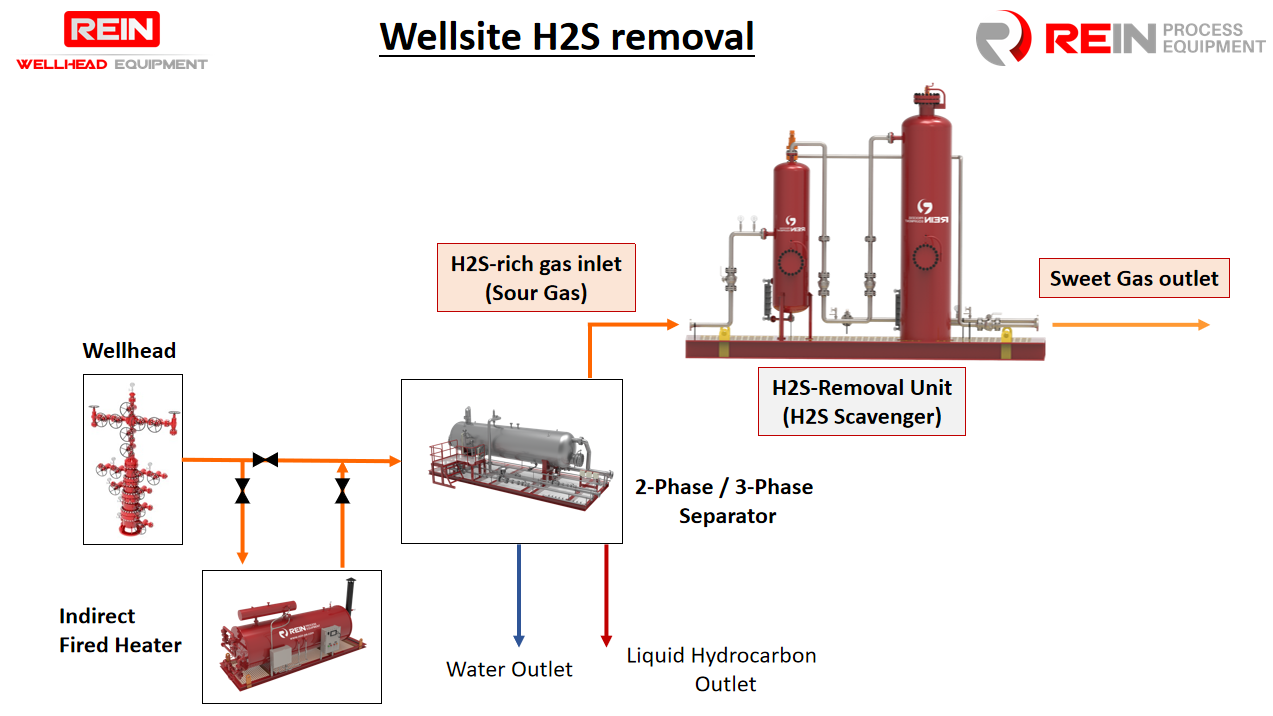

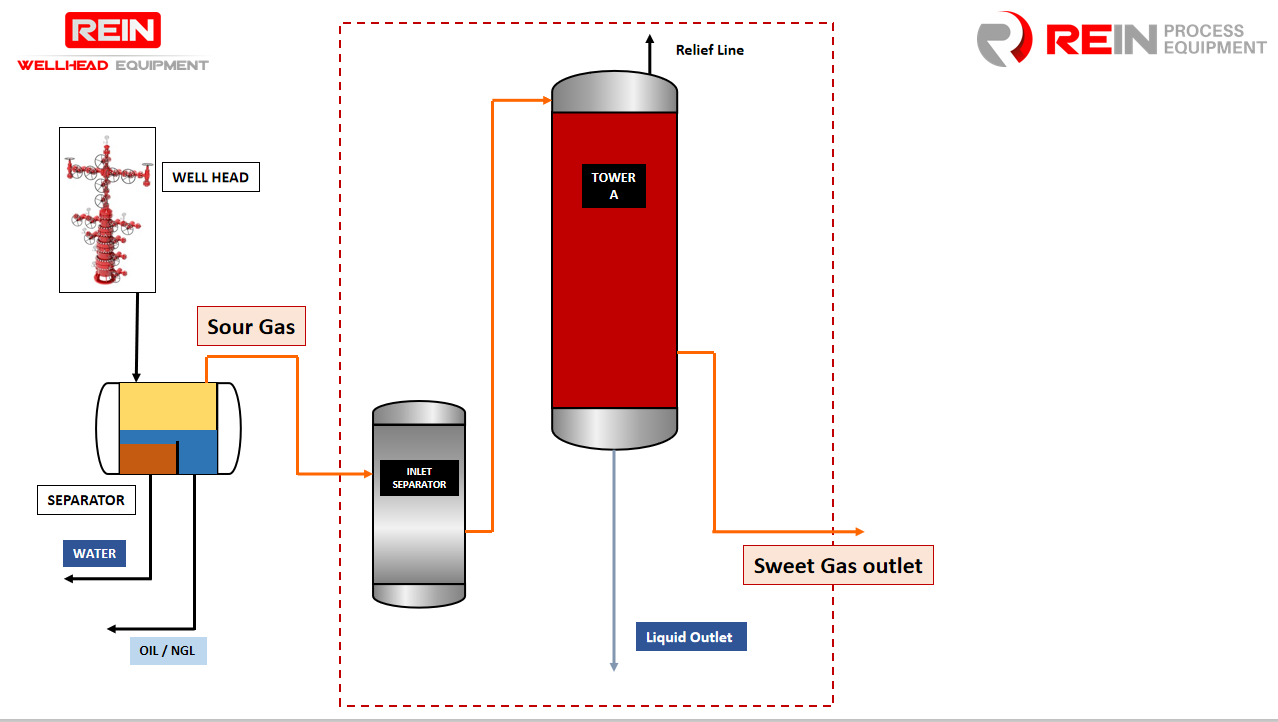

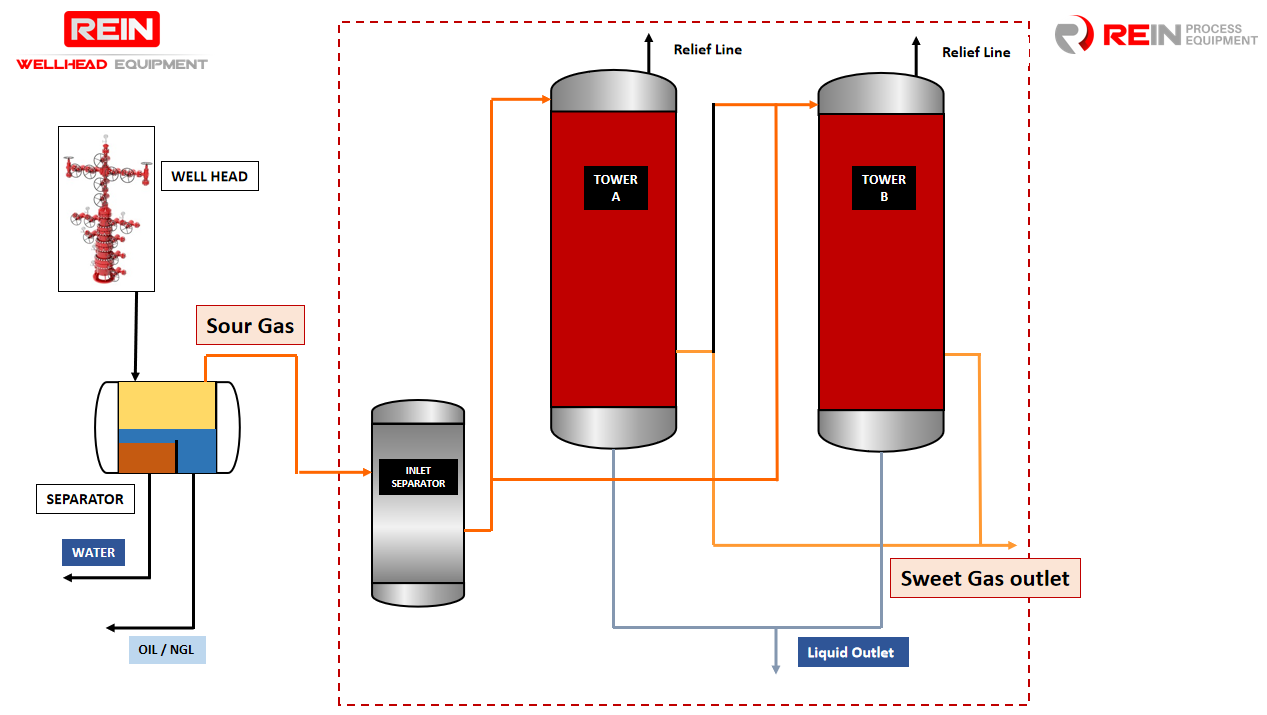

Rein offers cost-effective and high-performance hydrogen sulfide removal units for oilfield Fast Track application, which can lower H2S amount to pipeline specification right at the wellsite. Vertical vessel (process column) with outer and internal structure accommodates H2S Scavenger, non-hazardous porous solids, which contains high amount of iron oxide. Vessel bed upstream vertical inlet separator is employed to remove liquid droplets from natural gas stream. This prevents solid scavengers being blocked by moisture and ensures proper H2S removal from natural gas.

The iron sponge process is simple, yet requires professional approach, proper calculation of the vessel sizing, and most importantly, requires quality H2S scavengers to handle required amount of H2S, gas flowrate and gas stream pressure. Vertical Vessel is designed as per ASME, PED or GB standards and shall be made from corrosion-resistant construction materials, which are specified in the certain regulatory documents, such as NACE MR0175, ISO 15156 or equal standard as per GB.

Team of chemical and mechanical engineers of Rein developed reliable and cost-effective equipment for fast track oilfield H2S-removal. After receiving inquiry, we will conduct process and mechanical calculations, select proper solid H2S Scavenger to meet client’s expectation for performance, price, and delivery period. Rein has developed solutions because of rising demand for gas desulfurization units both in domestic and international markets, which will allow gas processors to treat and export gas with lowered H2S amount as per export pipeline specifications.

Rein also offers gas sweetening unit using liquid H2S removal technology. Liquid H2S Scavenger is also widely applied for H2S removal by absorption process. Rein offers gas sweetening units using following liquid scavengers.

Triazine method

Triazine liquid desulfurizer is a non-renewable high-efficiency desulfurizer. Generally, the aqueous solution of triazine compounds is directly injected into the feed oil and gas pipeline in oil and gas fields, which makes the aqueous solution of triazine compounds react irreversibly with hydrogen sulfide in oil and gas to form thiadiazine, so as to achieve the purpose of removing hydrogen sulfide in natural gas. The desulfurization products are all water-soluble liquids, which can be biodegraded, non-toxic and harmless, and have the characteristics of safety, reliability and environmental protection.

triazine

1.Complex iron method

The H2S-containing gas enters the bubble column and is quickly and fully mixed with the circulating solution in the column to absorb H2S in the gas phase. After reaching the standard, the gas is discharged from the top of the bubble column and sent to the downstream. The sulfur is absorbed by the catalyst in the column. The sulfur-containing solution is discharged from the bottom of the column and cooled by the solution cooler before being sent to the oxidation tank. In the oxidation tank, the crystal elemental sulfur falls to the funnel-shaped cone bottom by gravity, and the separated sulfur slurry is sent to sulfur recovery treatment. At the same time, the air bubbled to regenerate the catalyst. The circulating solution discharged from the oxidation lees is pressurized by the solution circulating pump, and then sent to the bubble column to absorb H2S in the gas phase. The circulating solution used in the process is complex iron system with pH value of 8.0~8.5, and 5 chemicals are added to ensure its normal operation. The purification degree of the desulphurized gas can reach < 5mg/m3, and some mercaptan can also be removed.

2. Amine method

The active amine desulfurization system is mainly used to remove H2S gas from natural gas to avoid corrosion of equipment in the subsequent process. Acid gas enters the amine absorber and reacts with the lean liquid entering the absorber through countercurrent reaction in the packing section to remove the H2S gas. The gas phase out of the absorber enters the filter at the top of the column to remove the gas droplets, and then enters the downstream system.

The rich liquid from the bottom of the absorber is depressurized by choke valve, and then enters the amine-rich liquid flash tank. After releasing non-condensable gas, it enters the lean-rich liquid heat exchanger to exchange heat with the lean liquid from the bottom of the regenerating column. After heating up, it enters the regenerating column for mass transfer with the rising gas. The heat required for regeneration is provided by the reboiler. The lean liquid exits the bottom of the regenerating column and enters the lean-rich liquid heat exchanger to exchange heat with the rich liquid. After being cooled by the lean liquid cooler, the lean liquid enters the lean liquid buffer tank. The desalted water and amine liquid are supplemented in the lean liquid buffer tank to meet the water balance and volume loss of the system. The lean liquid circulating pump is used to boost the pressure and deliver the lean amine liquid to the upper part of the amine absorber to complete the amine liquid circulation. The regeneration gas from the top of the regenerating column is condensed and cooled by the reflux cooler, and enters the overhead separator. The condensate is mainly water, which flows back to the amine liquid storage tank, and the acid gas is recovered or directly vented.

Feel free to contact Rein for H2S Scavenger Equipment and desulfurizers, as well as gas sweetening unit by absorption processes. We will provide immediate technical support, consultation, and proposal. Below are basic parameters of Iron sponge beds. Please note parameters are for reference only because each unit shall be calculated based on natural gas properties of certain oilfield.

Parameters

Gas Flowrate | 0-280 000 Nm3/day |

H2S Content at inlet | Below 1000 ppm |

H2S Content at outlet | Below 2 ppm |

Operating pressure | Atmospheric – 9.9 MPa |

Operating temperature | 10-79 °C |

Type of hydrogen sulfide removal agent | Solid type: · Iron oxide · Ferric hydroxide · Activated Carbon Liquid scavengers · Triazine · Complex iron · Amine |

Type of gas sweetening equipment | Single fixed-bed column; Dual fixed-bed column; Fixed bed column(s) with gas filters; Mechanically operated; Digitally operated; Contact tower with injection system |

Type of transport shipment | Filled bed with solid scavengers; Skid-mounted for “plug-and-play” installation; Disassembled for site installation (usually large sizes) |

Chemical Agents for Hydrogen Sulfide Removal

H2S Scavenger is a special non-hazardous, porous solid desulfurizing agent, which are used to lower H2S amount in natural gas to meet pipeline specification. Rein offers wide range of solid H2S scavenger, also known as Iron sponge, to handle various working conditions. Our solid H2S scavenger contains high amount of iron oxide, special chemical substances to enhance bed performance, and withstands high operating pressure.

Iron oxide is impregnated in special chips, which are non-hazardous, easy to handle and transport. Rein offers packing in 25 kg bags or 1000 kg industrial big bags. Rein will provide all necessary documentations and certifications for domestic and international transportation.

Application

· H2S scavenging at wellhead

· Natural gas sweetening

· Coke oven gas treatment

· Metallurgy

· Chemical industry

· Textile

· Environment protection systems

· Other gas-purifying systems

Types | |||

Common iron oxide-based iron sponge | Ferric Hydroxide with high iron concentration | Activated carbon | Customized as per client’s condition |

Regular desulfurizer is a high-efficiency gas purifier made of iron oxide as the main active component and other accelerators added. At 0~80℃, it has high removal performance for hydrogen sulfide. Mainly used for desulfurization of hydrogen sulfide in oil field gas, coke oven gas and other gas. The desulfurizer has the characteristics of easy operation, high purification and low bed resistance. | The desulfurizer is chemically synthesized with additives such as activated iron oxyhydroxide, pore forming agent, organic binder and other auxiliary agents, and is prepared by extrusion and drying after activation. Compared with traditional compound desulfurizers, it has the characteristics of high sulfur capacity, high strength and low resistance. It has the advantages of simple equipment, convenient operation, large sulfur capacity, high purification, strong adaptability and repeated use of recycling. Compared with regular desulfurizer, it can reduce the filling times, the loading cost and the environmental treatment cost of solid waste. It is widely used to remove H2S in natural gas, gas desulfurization, CNG natural gas, coke oven gas, shift gas, food carbon dioxide, carbon dioxide regeneration gas, petroleum refining gas, biogas and other gases, and has certain removal effect on organic sulfur. | The desulfurizer is made of high-quality carbon raw materials, adding certain binder and cocatalyst, forming through screening, carbonization and activation to form black columnar particles. It has the characteristics of high activity, high porosity, large sulfur capacity, high desulfurization efficiency, good mechanical strength, good water resistance, easy regeneration, and not easy to be broken under high temperature and high pressure. It is mainly used for the purification of various sulfides in coke oven gas, city gas, chemical industry feed gas and other gases, and has unique high-efficiency and high-precision purification effects for the removal of organic. | Rein also offers customization of H2S adsorbent compound in case of operating conditions require special H2S scavenger. Feel free to contact Rein in case of H2S scavenger with special compound is required. |

If you require any further information,feel free to contact us

We would be glad to provide you immediate technical assistance and cost-effective proposal!

CONTACT BY PHONE CONTACT BY EMAIL