CONTACT US

-

Mob:

+86 135 2595 3919 -

Tel:

+86 135 2595 3919 -

Email:

sales@rein-pe.com -

Add

402, B40, TusCity, Suzhou Industrial Park, Suzhou, 215122, Jiangsu, China

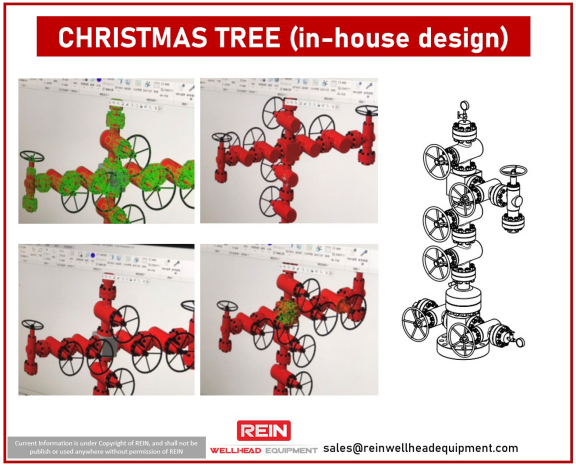

Christmas Tree

Christmas Tree

Christmas Tree (X-mas tree) is a special mechanical valve assembly which provides service to operator for opening, closing, controlling, and monitoring well stream. Christmas Tree is used for oilfield works, such as hydrocarbons production, enhanced oil recovery, hydraulic fracturing, well testing, and flowback. Configuration of Christmas Tree depends on the requirement of the operator or oilfield service company or vendor’s suggestions from serial production.

Below is a basic description of Christmas tree:

Christmas tree is the equipment located above the tubing head. The bottom valve often called the master valve is the primary means for completely shutting in the well. T-type fittings allows for redirection of the vertical flow stream to a horizontal flow line. For a flowing well the produced fluids before entering the surface flow line must pass through the smallest restriction in the surface flow equipment the choke. The choke is used to control the production, perhaps to prevent sand production or to maintain the most efficient rate for the well. The choke restricts the area available for flow through a beam or orifice of a specified diameter that must be inserted into the choke body. The smaller the diameter of the beam the lower the production rate. There are two different kinds of chokes, the positive chokes with interchangeable beans, and adjustable chokes, which allow the choke size to varied more easily. Tubing pressure is measured upstream that is on the wellhead side of the choke by pressure gauge.

The choke is used to control the production, perhaps to prevent sand production or to maintain the most efficient rate for the well. The choke restricts the area available for flow through a beam or orifice of a specified diameter that must be inserted into the choke body. The smaller the diameter of the beam the lower the production rate. There are two different kinds of chokes, the positive chokes with interchangeable beans, and adjustable chokes, which allow the choke size to varied more easily.

Positive choke is one kind of chokes with interchangeable beans, used to control the production, perhaps to prevent sand production or to maintain the most efficient rate for the well. The choke restricts the area available for flow through a beam or orifice of a specified diameter that must be inserted into the choke body. The smaller the diameter of the beam the lower the production rate.

Adjustable choke is another kind of chokes, which allow the choke size to varied more easily. As positive choke, adjustable choke is used to control the production, perhaps to prevent sand production or to maintain the most efficient rate for the well. The choke restricts the area available for flow through a beam or orifice of a specified diameter that must be inserted into the choke body. The smaller the diameter of the beam the lower the production rate.

Christmas tree usually consists of following components:

· Master Valve

· Slab Gate Valve

· T-Type Fitting

· Cross

· Adapter

· Positive (Bean) Choke / Adjustable Choke

· Pressure Gauge

· Emergency Shutdown Valve

Injection port for electric pump (in case of lifting is required)

Main Technical Specification

Standards | API 6A / ГОСТ 13846-89 / |

Nominal diameter for outer pipe connection, in.(mm): | 2.1/16” - 7.1/16” (50-150) 7.1/16” - 21.1/4” (150-530) |

Nominal Pressure, psi (MPa) | 2000 psi – 15000 psi (14-105) |

Environment temperature | from -60°С to +40°С |

Working temperature | LU (51℉/-46℃ ~ 250℉/121℃) |

Material Grades | AA, BB, CC, DD, EE, FF, HH, FF |

Specification level | PSL1 - PSL4 |

Performance level | PR1, PR2 |

Material Class | Min. Material Requirements | |

Outer parts | Internals | |

AA | Carbon or Low Alloy Steel | Carbon or Low Alloy Steel |

BB | Carbon or Low Alloy Steel | Stainless Steel |

CC | Stainless Steel | Stainless Steel |

DD | Carbon or Low Alloy Steel | Carbon or Low Alloy Steel |

EE | Carbon or Low Alloy Steel | Stainless Steel |

FF | Нержавеющая сталь | Stainless Steel |

HH | Corrosion Resistant Alloy | Corrosion Resistant Alloy |

ZZ | Determined by User | Determined by User |

Note: Classes from DD shall be NACE MR0175/ISO 15156 compliant

API Classification | Operating Temperature | |||

Min (°C) | Max (°C) | Min (°C) | Max (°C) | |

K | -60 | 82 | -75 | 180 |

L | -46 | 82 | -50 | 180 |

N | -46 | 60 | -50 | 140 |

P | -29 | 82 | -20 | 180 |

S | -18 | 60 | 0 | 140 |

T | -18 | 82 | 0 | 180 |

U | -18 | 121 | 0 | 250 |

V | 2 | 121 | 35 | 250 |

X | -18 | 180 | 0 | 350 |

Y | -18 | 345 | 0 | 650 |

Rein Wellhead Equipment (REIN WE) is the API 6A slab gate valve manufacturer in China, which offers wide variety of valve and valve assemblies. We strictly follow assigned codes & standards to meet the operational and environmental requirements of the clients. Feel free to contact us to receive quotation or technical assistance concerning API 6A slab gate valves and other oilfield equipment.

If you require any further information,feel free to contact us

We would be glad to provide you immediate technical assistance and cost-effective proposal!

CONTACT BY PHONE CONTACT BY EMAIL