CONTACT US

-

Mob:

+86 135 2595 3919 -

Tel:

+86 135 2595 3919 -

Email:

sales@rein-pe.com -

Add

402, B40, TusCity, Suzhou Industrial Park, Suzhou, 215122, Jiangsu, China

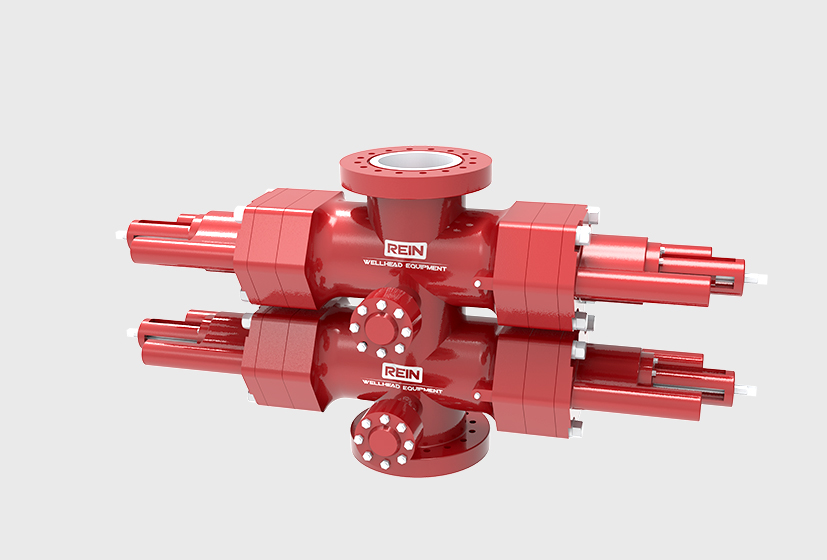

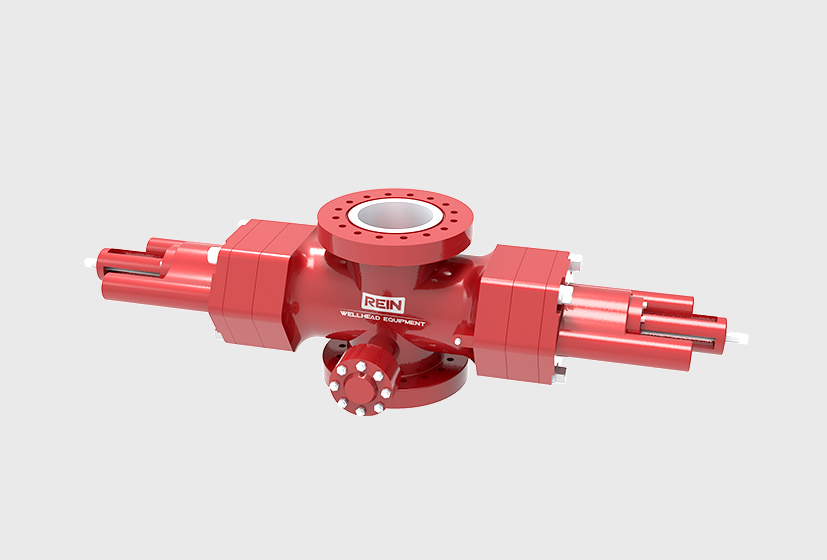

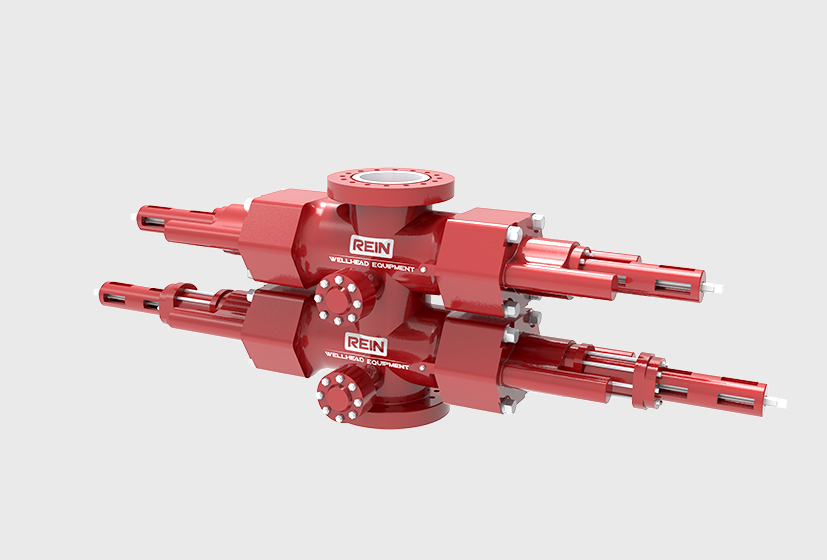

Ram BOP

Ram BOP

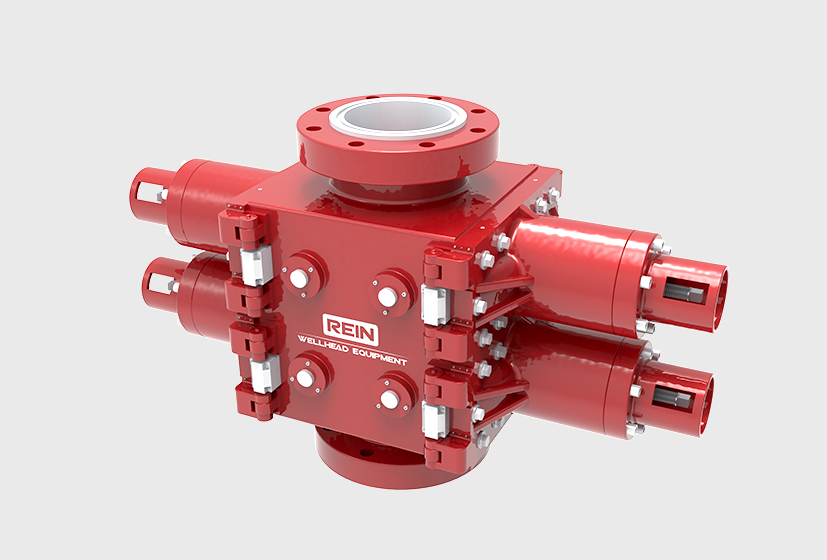

Ram blowout preventer (Ram BOP) is a special assembly used during drilling as part of blowout prevention system. The shut-off valves in ram preventers close by forcing or ramming themselves together. Ram BOPs close the well by rams which operate in unison and actuated by hydraulic cylinders. Ram BOP consists of BOP body, hydraulic open and close ports, bonnet, rams, bonnet seals, ram guide pins, connecting rod seals. Ram BOP has several types of rams, such as Pipe Ram, Blind Ram, Blind Shear Ram and Shear Ram. Locking Screw Housing consists of operating piston, locking screw, bonnet bolt, bonnet, ram change piston, ram change cylinder, operating cylinder, intermediate flange, plastic packing fitting, lifting eye.

Intermediate flange separates BOP hydraulic system from the well bore ladings and contains well bore pressure. BOP body is main pressure-containing vessel which contains well bore pressure. Drilling operator usually determines specification of outlets and spools. Hydraulic ports provide means of connecting hydraulic lines for opening and closing rams, as well as providing means of maintenance. Ram change piston designed to open the bonnet assembly, as well as to allow close pressure to reach the close side of the operating piston. Replaceable sealing is provided by ram change cylinders. BOP Bonnet is a special part of BOP for hydraulic system.

Ram BOP operation principle applies hydraulic pressure to open and close the rams. Hydraulic pressure applied through the ram closed port in the BOP body moves the BOP’s operating piston inwards closing the rams. The rams are opened by hydraulic pressure applied through open ports.

Operating fluid for onshore operation is a light hydraulic oil, which is most recommend type of fluids. Fuel oil is not recommended as it causes damage to rubber seals. Another type of operating fluids is water but having lubricant and antifreeze as a component of water mixture. Water mixture is recommended mostly for offshore drilling operations.

Maintenance of BOP consists of several operations, including bonnet opening and closing. To move the bonnet away from the BOP, the bonnet bolts shall be unscrewed, and hydraulic pressure shall be applied to closed port of ram, which provides access to the rams and other parts for maintenance. The bonnet is closed by applying hydraulic pressure though open port. Then, rams are pulled outward towards the bonnets before the bonnets begin moving toward the preventer body, assuring that rams never obstruct the bore with pipe in the hole. Hydraulic pressure holds the bonnets closed until the bonnet bolts are screwed back. Another maintenance work with BOP is bolt tensioner operation in BOPs with bolt tension system. The purpose of this operation is bonnet opening for removing bonnet bolt nut, which applies pressure to tensioner unit and its piston acts against the bolts. This stretches portion of the bolts between the threads at the tensioner and the treads in BOP body.

In Ram BOP, wedge lock mechanism can be applied. The principle in U BOP also applied hydraulic pressure which locks and unlocks by pressure ports, thus opening and closing ram BOP.

Range of operating pressure of ram BOP is between 2000 and 15000 psi. Ram BOP is designed, fabricated, and tested as per API Spec. 16A.

Rein Wellhead Equipment offers quality and cost-effective Ram BOPs from China, which are available in many sizes and pressure rating meeting the requirements of the client.

Pressure

psi | 2000 | 3000 | 5000 | 10000 | 15000 |

MPa | 13.8 | 20.7 | 34.5 | 69.0 | 103.5 |

Bore Size

Inch | 7-1/16 | 9” | 11” | 13-5/8” | 16-3/4” | 18-3/4” | 21 1/4 |

Hydraulic connection size

NPT | 1” |

Connection (Top - Bottom)

Studded - flanged

Flanged - flanged

If you require any further information,feel free to contact us

We would be glad to provide you immediate technical assistance and cost-effective proposal!

CONTACT BY PHONE CONTACT BY EMAIL