CONTACT US

-

Mob:

+86 135 2595 3919 -

Tel:

+86 135 2595 3919 -

Email:

sales@rein-pe.com -

Add

402, B40, TusCity, Suzhou Industrial Park, Suzhou, 215122, Jiangsu, China

API 6A Choke Valve

API 6A Choke Valve

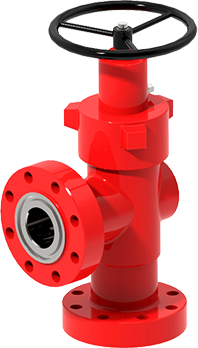

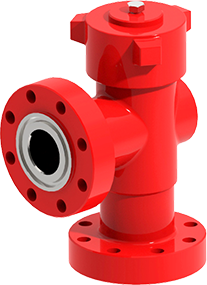

The choke valve is the major component of the Christmas tree and Manifold, mainly used for controlling the production rate of an oil well at a working pressure of up to 20,000 psi. The choke valve can be classified as adjustable choke valve and positive choke valve. The adjustable choke valve is designed to adjust the effective area available, for the flow to control the production rate, through rotating the hand wheel. The positive choke valve is designed to control the production rate through changing flow beans.

These choke valves are available in different configurations as below:

• Positive bean configuration

• Needle and Seat configuration

• Cage type configuration

Adjustable Choke Valve

Positive Choke Valve

Specifications

• Nominal diameter: 2.1/16” ~ 4.1/16”

• Working pressure: 2000 PSI ~ 20000 PSI

• Working media: oil, natural gas, mud

• Working temperature: LU ( 51℉/-46℃ ~ 250℉/121℃)

• Material grades: AA, BB, CC, DD, EE, FF, HH

• Specification level: PLS1 ~ PSL4

• Performance level: PR1 ~ PR2

Features

• Long life and low maintenance

• Body to bonnet contact behind the O-ring seal eliminates bonnet seal extrusion

• A locking device is set on stem

• Ideal for many flow regulating services and easily converted to a positive choke

• The stem of adjustable choke is made of high strength alloy steel. The material has the feature of abrasion resistance, erosion resistance and reliable serviceability

• The valve and seat can be removed by hand, without special tools and without removal of the valve body from the line, by simply removing the bonnet

• Drive has manual, hydraulic and gear transmission forms

• Connections have flange, thread and hub

Technical drawings

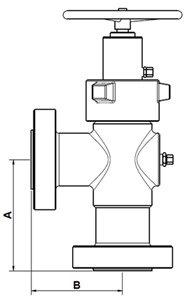

Adjustable Choke Valve

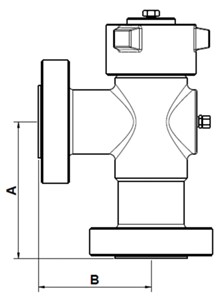

Positive Choke Valve

Flanged End Dimensions (mm)

Size | Working Pressure (psi) | A | B | Ring No. |

1” Maximum Orifice | ||||

2.1/16” | 2000 | 165 | 150 | R 23 |

2.9/16” | 2000 | 170 | 160 | R 26 |

2.1/16” | 5000 | 203 | 175 | R 24 |

2.9/16” | 5000 | 210 | 175 | R 27 |

2.1/16” | 10000 | 224 | 195 | BX 152 |

2.9/16” | 10000 | 237 | 208 | BX 153 |

2.1/16” | 15000 | 262 | 225 | BX 152 |

2.9/16” | 15000 | 298 | 267 | BX 153 |

2” Maximum Orifice | ||||

3.1/8” | 2000 | 230 | 185 | R 31 |

2.9/16” | 5000 | 265 | 195 | R 27 |

2.9/16” | 10000 | 298 | 264 | BX 153 |

2.9/16” | 15000 | 298 | 264 | BX 153 |

3.1/8” | 3000 | 298 | 225 | R 31 |

3.1/8” | 5000 | 298 | 225 | R 35 |

3.1/16” | 10000 | 298 | 264 | BX 154 |

3.1/16” | 15000 | 298 | 264 | BX 154 |

4.1/16” | 3000 | 298 | 264 | R 37 |

4.1/16” | 5000 | 298 | 264 | R 39 |

4.1/16” | 10000 | 350 | 289 | BX 155 |

3” Maximum Orifice | ||||

4.1/16” | 3000 | 298 | 264 | R 37 |

4.1/16” | 5000 | 298 | 264 | R 39 |

If you require any further information,feel free to contact us

We would be glad to provide you immediate technical assistance and cost-effective proposal!

CONTACT BY PHONE CONTACT BY EMAIL