CONTACT US

-

Mob:

+86 135 2595 3919 -

Tel:

+86 135 2595 3919 -

Email:

sales@rein-pe.com -

Add

402, B40, TusCity, Suzhou Industrial Park, Suzhou, 215122, Jiangsu, China

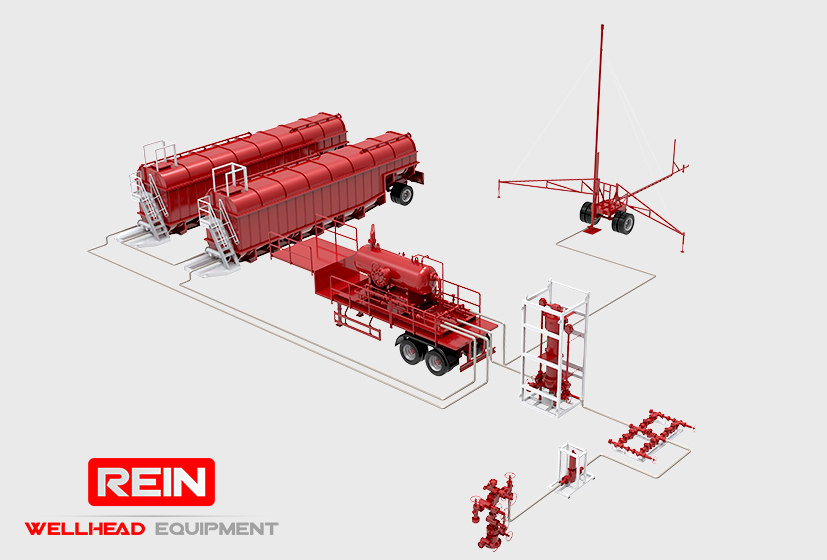

Flowback Equipment & System

Flowback Equipment & System

Frac flowback system is designed to remove debris and other impurities after hydraulic fracturing, while separating valuable liquid hydrocarbons for further disposal. Flowback and well test system consists of emergency shutdown valve, ESD panel, choke manifolds, debris (junk) catcher, sand traps, line heaters, high-stage and low-stage separators, frac tanks, flare stacks, hydraulic control panel, HP piping, LP piping, fittings and other necessary equipment for oilfield operations.

Emergency Shutdown Valve

Emergency Shutdown Valve is a standalone safety device which is designed to shutdown the flow line, protecting upstream equipment and personnel from uncontrolled pressure and temperature. Emergency Shutdown Valve works on “fail-safe” mode, and has actuated hydraulic actor, which keep line open under hydraulic pressure (2500-3000 psi). ESD console consists of oil pump, pneumo-hydraulic pump, push bottoms, and other devices required for operation.

· Pressure rating: 5000-15000 psi

· Emergency Shutdown Period: less than 5 sec.

· Service: standard, sour

Choke Manifold

Choke manifold is designed to reduce the flowrate, thus, pressure, conditioning stream for further handling in upstream equipment. Choke manifold consists of several gate or plug valves, as well as choke valves.

· Pressure rating: 5000-15000 psi

· Choke Type: positive (bean) and/or adjustable

· Service: standard, sour

Debris (Junk) Catcher

Debris Catcher or Plug Catcher is designed for bulk removal of debris formed during hydraulic fracturing. Plug catcher has special inserts which catches unwanted substances, cleaning the flow.

· Pressure rating: 5000-15000 psi

· Plug Catcher Type: Single Barrel or Dual Barrel

· Service: standard, sour

Sand Trap

Sand Trap is vertical mechanical device designed to remove smaller size sands and solids from flow stream applying gravitational force, which drives heavier substances downwards, while lighter substances (oil, gas, water) flows from the top.

· Pressure rating: 5000-15000 psi

· Sand Trap Type: Spherical, Cyclone, Vertical with Insert

· Service: standard, sour

Horizontal Separators

Horizontal Separator are one of the most important oilfield equipment, which separates well fluids into three or two phases. Horizontal separators are either designed for high or low pressure depending on the application regime. Horizontal separators have one inlet line, gas outlet line, relief line, water outlet line, oil outlet line, which are equipped with valves and instruments. Liquid level is controlled by level controller or level switches. Gas pressure is controlled by pressure controller and control valve. Liquid and gas flow measurement devices is also available. Horizontal separator can be trailer-mounted for convenient mobilization from one well to another.

· Pressure rating: 250-2160 psi

· Phase: 2-phase, 3-phase, 4-phase

· Options: with winterized control cabinet for hosting all instruments

· Skid type: skid-mounted, trailer-mounted

· Service: standard, sour

Flare stack

Flare stacks, either 40 ft. or 60 ft. are designed to dispose free gas safely by burning it. Flare stacks can be skid-mounted or trailer-mounted for convenient mobilization and operation. Flare stacks have pilot and ignition system, allowing operator to operate safely.

· Height: 40 ft, 60 ft.

Frac tank

Frac tanks are special tanks which are designed to keep liquids coming from the well. Frac tanks can be designed with trailer base for convenient transportation and mobilization.

· Capacity: 200-500 bbl

Rein Wellhead Equipment, a division of Rein Process Equipment, provides complete packages for well clean-up, well testing, and early production facilities. Feel free to contact Rein for technical support and quotation. Rein is a manufacturer and supplier of flowback and well test equipment from China.

If you require any further information,feel free to contact us

We would be glad to provide you immediate technical assistance and cost-effective proposal!

CONTACT BY PHONE CONTACT BY EMAIL